RAILWAY

SLEEPERS

WEGH GROUP, after many years in the production of sleeper plants, decided to acquire product as well as process technical expertise more than 10 years ago.

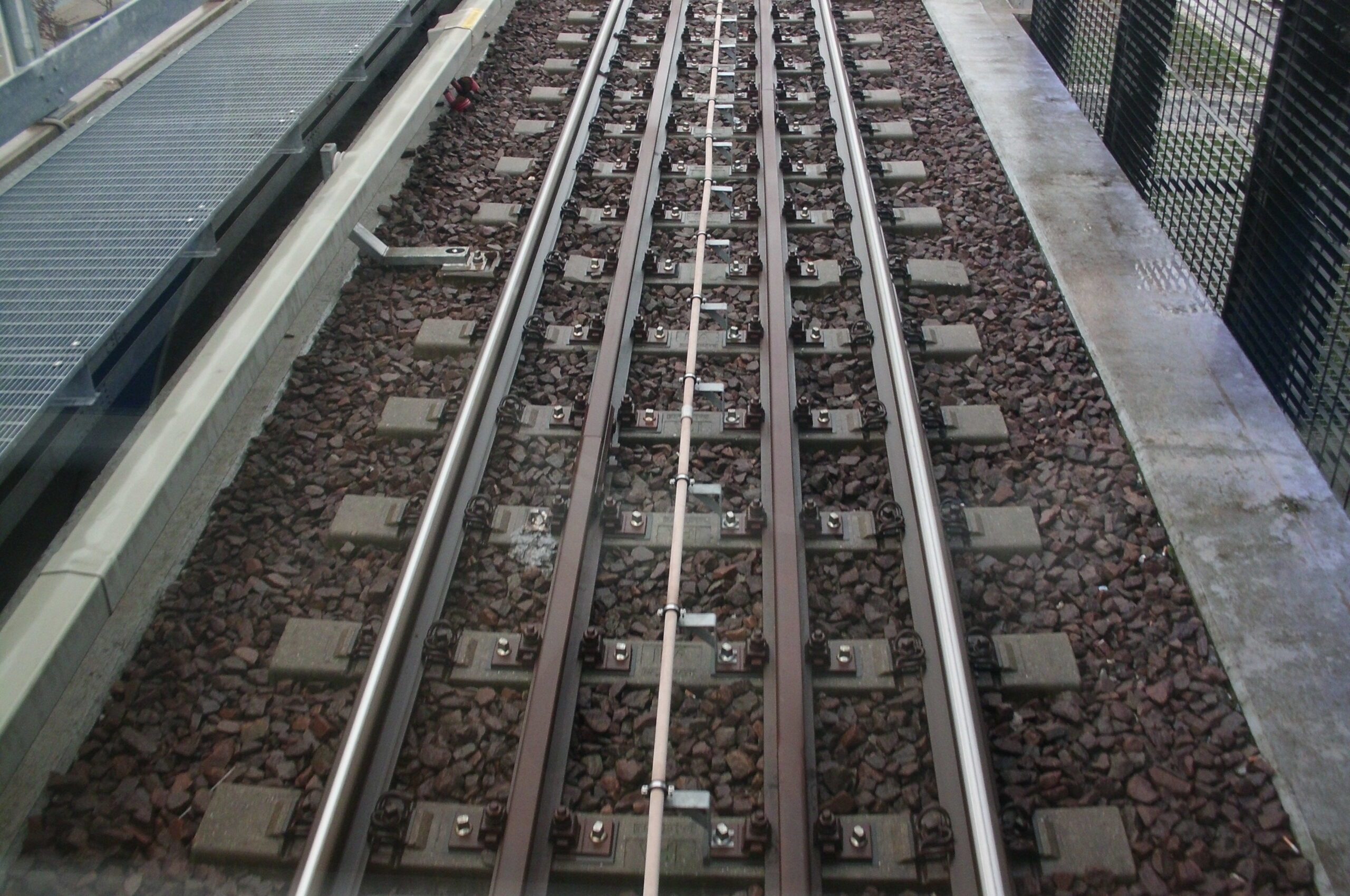

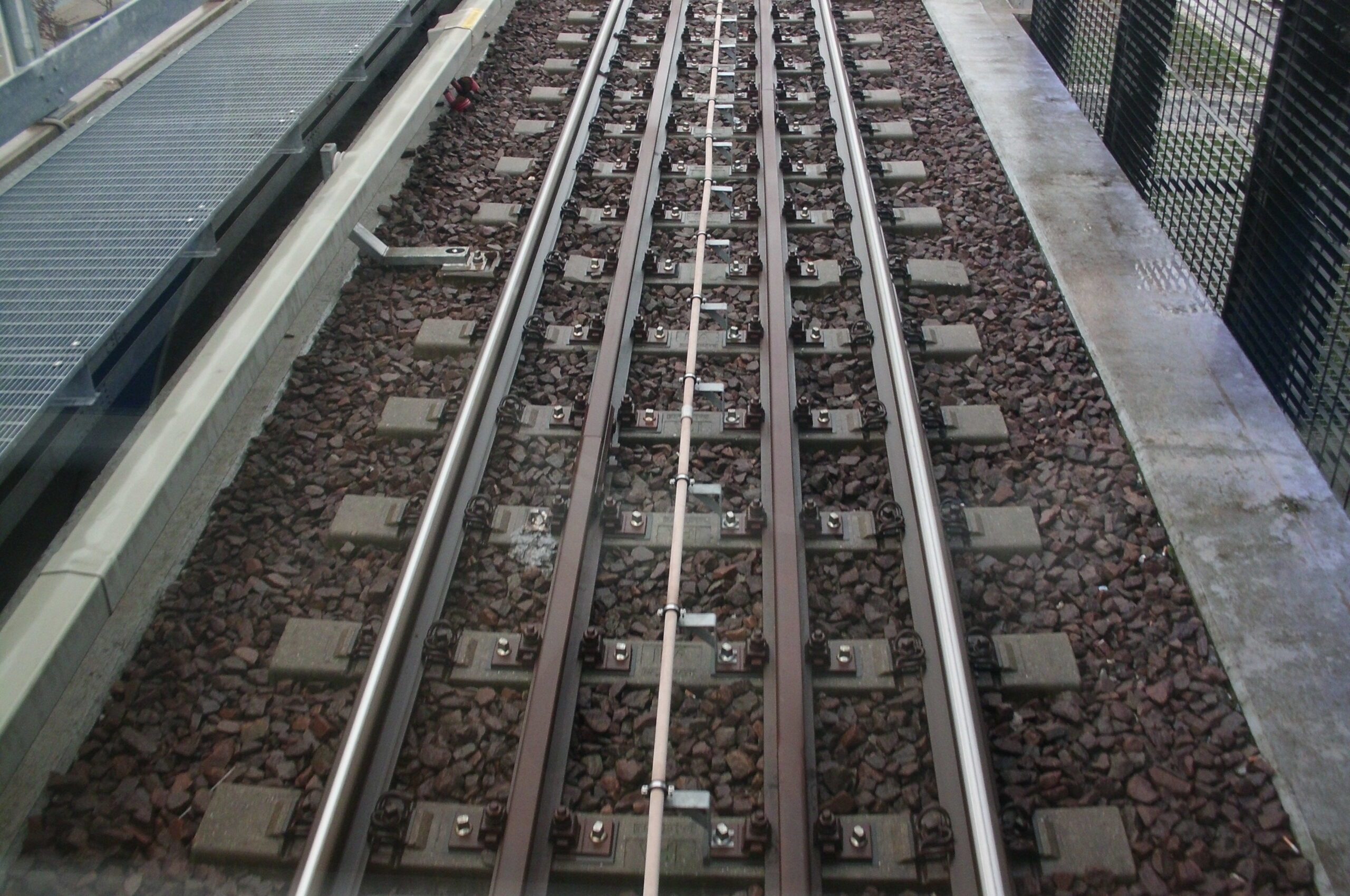

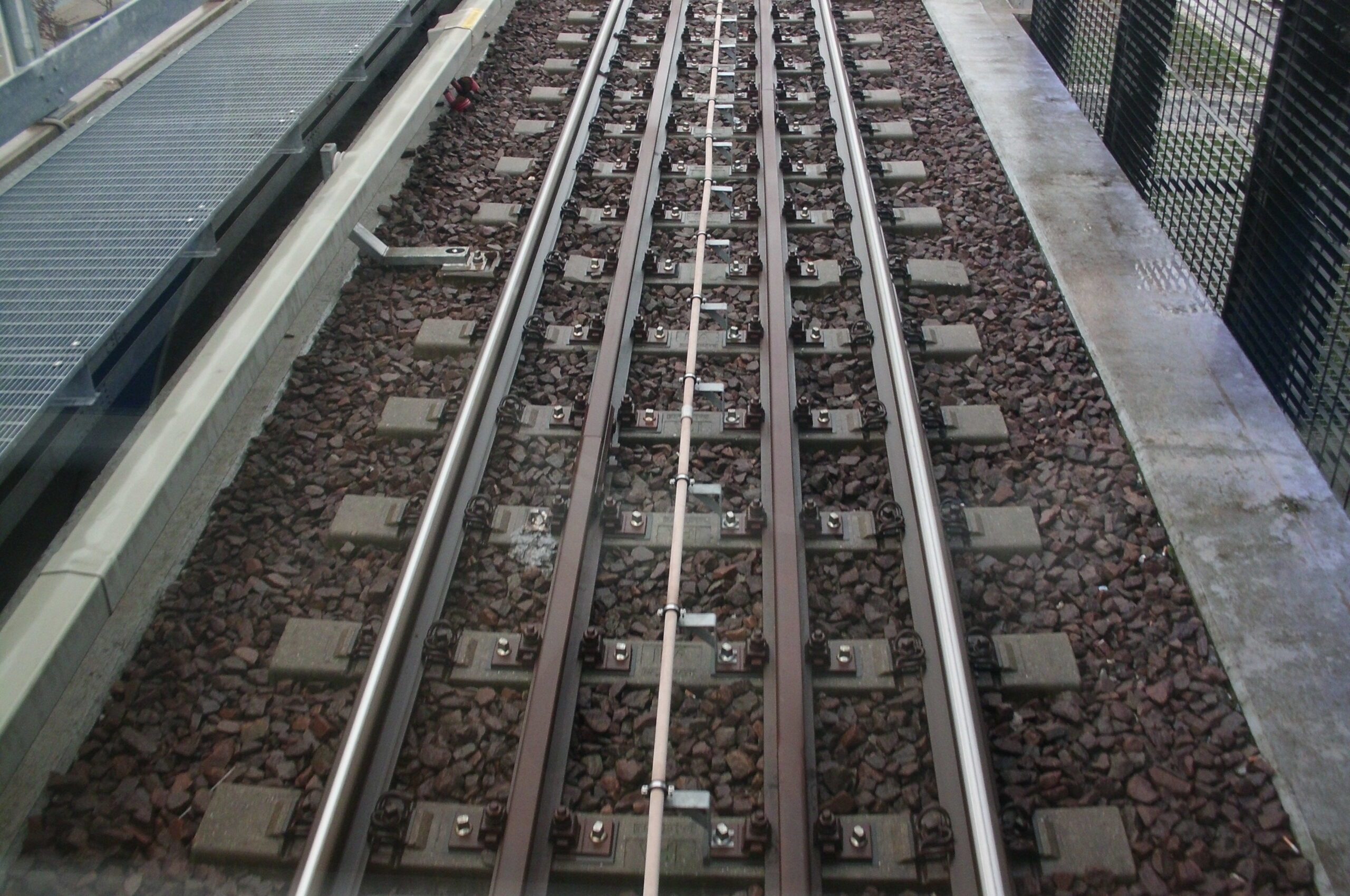

Reinforced concrete railway sleepers

prestressed vibrated concrete (PRC)

The production of railway sleepers is one of our company’s strengths: the Business Unit is entirely dedicated to these products, made in different types and for different types of direct and indirect connections (such as Vossloh, Pandrol and Denik). The models are suitable for both conventional, standard- and metric-gauge railway lines and high-speed lines. In addition, we manufacture turnout bearers and tramway sleepers

WEGH Group’s PRC (prestressed reinforced concrete) railway sleepers are distinguished by safety, reliability and durability: values that the company guarantees every day, thanks to decades of experience in the sector, the commitment of a highly qualified team and a production process with high-performance technological plants.

The Sleepers Business Unit offers solutions, in the national and global market, in full compliance with local regulations, providing a complete service: from design to production and certification of products.

Quality First

The high standards of our sleepers are guaranteed by the constant controls of the Quality Assurance department, which checks materials and production processes with technological instruments and certified equipment in our laboratory. The sleepers are made with plants equipped with the best technologies to ensure the highest quality standards.

The use of high-performance pre-stressed concrete guarantees the sleepers high performance and durability.

The main advantages of prestressed reinforced concrete sleepers, compared with their wooden predecessors, are:

1. Durability

2. High resistance to loads and stresses;

3. Lower life cycle costs;

4. Environmental sustainability.

Sleepers types

There are numerous types of concrete sleepers designed and manufactured by our group. Prominent among these solutions, for example, is our patented UNICA G+P WEGH® sleeper: designed and built to be laid at glued insulating joints, it ensures adequate support and safe containment of related wiring and connections.

Manufacturing of High Speed Sleepers (HS)

HS sleepers must be designed to withstand different loads and speeds than normal lines. For this purpose we use suitable rubber under sleeper plates and USPs (Under Sleeper Pads). The latter make it possible to

– dampen friction between concrete and ballast, reducing the formation of fine dust;

– improve load distribution;

– reduce the frequency of tamping and ballast replacement operations.

Our HS turnout bearers and sleepers, therefore, provide high performance and lower life cycle cost.

Gauge of monoblock sleepers in PRC

-

The range of our sleepers offers several options for GAUGE:

1. Standard gauge, the classic 1437 mm gauge used in most of Europe, China, North America;

2. Oversized gauge, used in some South American countries, Russia, former USSR republics, India and other countries;

3. Metric gauge (Cap Gauge), used in many railways of the world;

4. Double gauge, in lines on which coaches and cars with different gauges can run;

5. Variable gauge, in the curved sections of railways.

Sleepers for anti-slide rails

Some of our sleepers are designed to accommodate anti-slide rails. These are added to the main rails to ensure operational safety, even on sections of line that, due to their particular conformation, may pose risks of train derailment.

Power rail sleepers

WEGH Group provides power rail sleepers as an alternative to electrified overhead lines, which allow high instantaneous currents to be drawn-an important consideration in high-traffic environments.

Gallery Sleeper

WEGH Group manufactures a specific sleeper – RFI GALLERY sleeper – equipped with USP mats and designed specifically for tunnels that have reduced elevation margins between the tunnel extrados and the rail plane and minimal lateral breakthroughs.

Full compliance with regulations

- WEGH Group is able to design, produce and validate concrete sleepers according to any national and international product and system standards (EN, AREMA, GOST, etc…) and the technical supply specifications of major operators, such as:R.F.I. (Rete Ferroviaria Italiana);

- D.B. (Deutsche Bahn);

- N.C.F. (Société Nationale des Chemins de fer Français);

- SBB CFF FFS (Ferrovie Federali Svizzere);

- D.I.F. (Administrador de Infraestructuras Ferroviarias);

- F.M. Mozzambico – Portos e Caminhos de Ferro de Moçambique;

- A.F.E. Uruguay – Administración de Ferrocarriles del Estado;

- RZD Russia;

- U.T.Y. Uzbekistan – Uzbekiston Temir Yollari;

- D.S.O. India – Research Designs & Standard Organisation;

- Trenes Argentino Argentina.

Need more information about WEGH Group’s signature railroad sleepers?