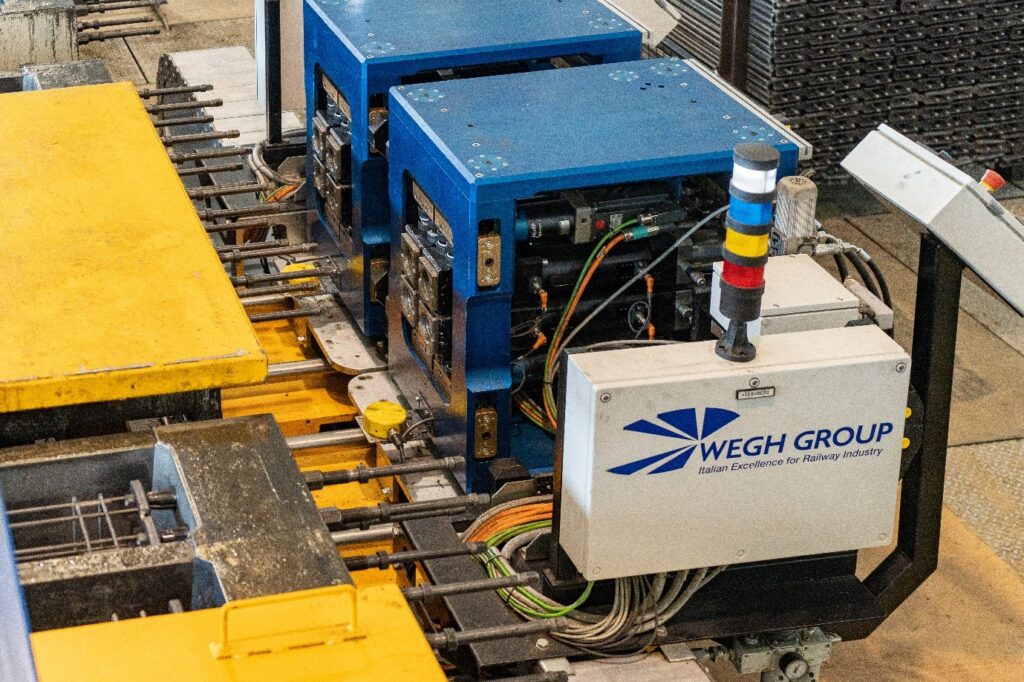

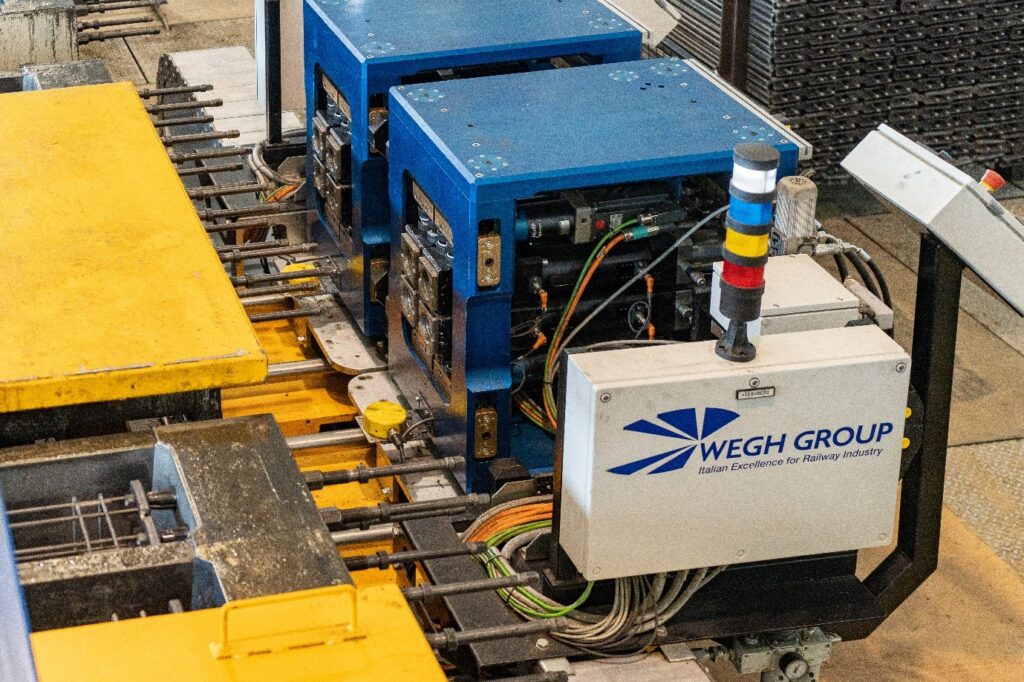

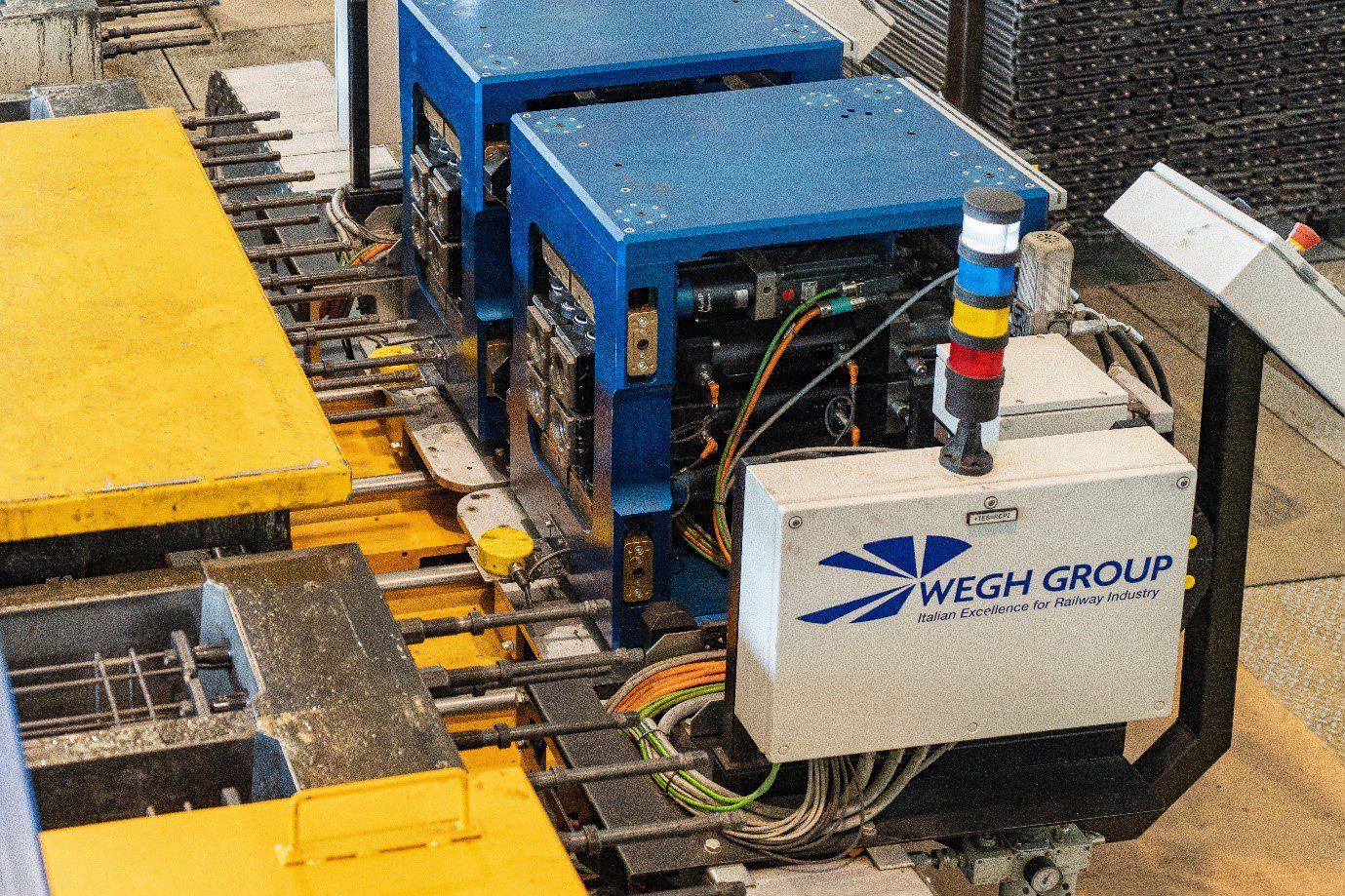

The combination of advanced electronic systems, combined with modern RFID technology, makes Wegh’s TS20 automatic tensioning machine a flexible and highly efficient machine.

The tensioning machine can carry out, autonomously, the necessary technical re-sets, modulating itself to the product to be manufactured. The TS20 identifies the type of mould being processed through passive RFIDs installed in each mould, which record information about the sleepers to be produced.

The TS20 tensioning machine quickly adapts its tensioning heads (position and tension) in accordance with the tie rod centre distances, guaranteeing high flexibility and mixed production.

The TS20 automatic tensioning machine is designed according to the Machinery Directive 2006/42/CE and is equipped with:

– complete process data recording system;

– dedicated support trolley for easy and quick maintenance;

– mould lifter and centering device.