Level crossing systems

WEGH Group offers different types of system for level crossings, designed and developed according to the level of automation and power supply required, the type of track and the maximum speed of transit of trains on the line. WEGH Group systems are modular in design and can be implemented according to the degree of automation the customer requires.

Systems for the protection of level crossings: barriers and other devices

Our company offers solutions in full compliance with worldwide railway regulations and based on the specifications issued by RFI (Rete Ferroviaria Italiana), an organization internationally recognized for its high safety standards.

The latter are necessary to ensure the safety of both car’s drivers passing over the level crossing and train passengers.

When a train approaches, the level crossing systems receive the closing command from the rail sensors and, at the same time, the road side lights and bells are activated, signalling the imminent closure of the barriers.

As soon as these operations are completed and no alarms are raised, the SIL 4 safety core sets the train side signal to free transit.

The passage of the train on the crossing is monitored by an axle counter system which guarantees to perform the re-open the barriers in less than two seconds, only after the passage of the whole train carriages.

These operations involves a series of delicate steps that require reliable and safe solutions.

Quality and safety are at the core of our mission

With a consolidated Know-how. Wegh Group is manufacturing modular and configurable products, ranging from single safety components to complete systems for level crossing protection. Our company offers complete solutions for the safety protection of the level crossings area for national and suburban railways.

eLCSP SYSTEM (electronic Level Crossing Safety & Protection)

With a consolidated Know-how. Wegh Group is manufacturing modular and configurable products, ranging from single safety components to complete systems for level crossing protection. Our company offers complete solutions for the safety protection of the level crossings area for national and suburban railways.

eLCSP system (electronic Level Crossing Safety & Protection)

To ensure highest safety at level crossings, the WEGH Group has introduced the eLCSP system (acronym for Electronic Level Crossing Safety & Protection). It is an electronic command and control system which, through electronic microcontroller components (PLC, Programmable Logic Controller) in 2 out of 2 configuration, is able to guarantee the safety automation of the closing and reopening sequence of level crossings, managing the barriers machines, luminous-acoustic signal on the road side and luminous signals on the track side. Different scenarios can be configured with minimum hardware changes: a feature that guarantees a high level of flexibility.

eLCSP is supplied already configured for the application chosen by the customer, the relative software modules are in fact factory-preset, taking into account the specificities of the crossing. Furthermore, the eLCSP system does not require special maintenance, as there is a diagnostic system that operates through ad hoc sensors able to predict degradation states and advising the operator about maintenance cycles to perform.

The eLCSP system is certified Railway SIL 4 (Safety Integrity Level), the highest degree of safety integrity, defined as the level of risk reduction guaranteed by a safety function, or specified as a target level of risk reduction. An example of the quality that distinguishes all of our group’s electronic level crossing systems.

eLCSP (electronic Level Crossing Safety & Protection)

SWITCH BOX FOR CROSSING SYSTEM TD96/2

Desires more information about our products For level crossings?

Scheda tecnica

CARATTERISTICHE PRINCIPALI

- SIL4 certified command & control system

- Safety core with dual PLC architecture

- TD96/2 shunting boxes (RFI approved)

- Powered by batteries, with charge control

- Train detection with electronic pedals and axle counter system

AVAILABLE OPERATING MODES

- Manual

- Semi-automatico

- Automatic

CONFIGURATIONS

- With full barriers, half-barriers, double pair of half-barriers, or light/acoustic only

- For single or double track line

- With double or single, steady or flashing light signals

OPTIONAL

- Chronological recording of events

- Power supply from photovoltaic panel

- Remote diagnostics

[/vc_toggle][vc_toggle title=”Technical Data”]Temperature range

-25°C ÷ +70°C

Maximum relative humidity

95%

Dimensions of the control cabinet

1000 x 600 x 1600 mm

Weight of the control cabinet

340 kg

Input voltage

220 V

System voltage

24 V cc

Available rod lengths

4 ÷ 8 m

Advance notice time

settable, 4 ÷ 60 s

Barrier closing/opening time

settable, 10 ÷ 15 s

Autonomy in the absence of battery charging

6 hours or 20 activations (in the most expensive configuration)

Maximum short-circuit current

4,5 kA

Differential tripping current of the earth leakage circuit breaker

30 mA

Insulation resistance

≥ 1 MΩ

Light emission of roadside signals

light visible at a distance of 100 m in the absence of fog

Acoustic emission of the bell

≥ 90 db/m

Control cabinet protection

IP55 (IP65 available upon request)

Scheda tecnica

CARATTERISTICHE PRINCIPALI

- SIL4 certified command & control system

- Safety core with dual PLC architecture

- TD96/2 shunting boxes (RFI approved)

- Powered by batteries, with charge control

- Train detection with electronic pedals and axle counter system

AVAILABLE OPERATING MODES

- Manual

- Semi-automatico

- Automatic

CONFIGURATIONS

- With full barriers, half-barriers, double pair of half-barriers, or light/acoustic only

- For single or double track line

- With double or single, steady or flashing light signals

OPTIONAL

- Chronological recording of events

- Power supply from photovoltaic panel

- Remote diagnostics

[/vc_toggle][vc_toggle title=”Technical Data”]Temperature range

-25°C ÷ +70°C

Maximum relative humidity

95%

Dimensions of the control cabinet

1000 x 600 x 1600 mm

Weight of the control cabinet

340 kg

Input voltage

220 V

System voltage

24 V cc

Available rod lengths

4 ÷ 8 m

Advance notice time

settable, 4 ÷ 60 s

Barrier closing/opening time

settable, 10 ÷ 15 s

Autonomy in the absence of battery charging

6 hours or 20 activations (in the most expensive configuration)

Maximum short-circuit current

4,5 kA

Differential tripping current of the earth leakage circuit breaker

30 mA

Insulation resistance

≥ 1 MΩ

Light emission of roadside signals

light visible at a distance of 100 m in the absence of fog

Acoustic emission of the bell

≥ 90 db/m

Control cabinet protection

IP55 (IP65 available upon request)

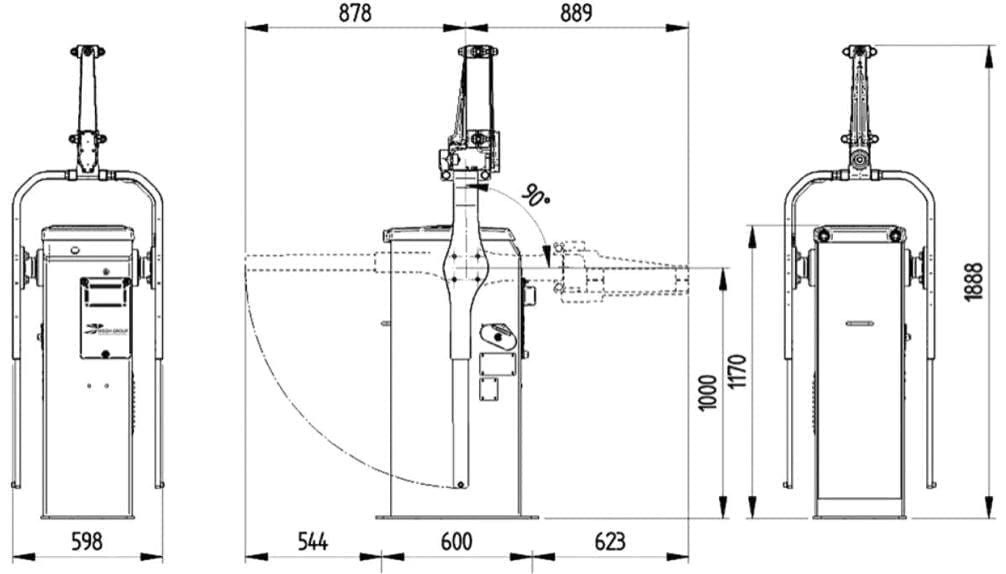

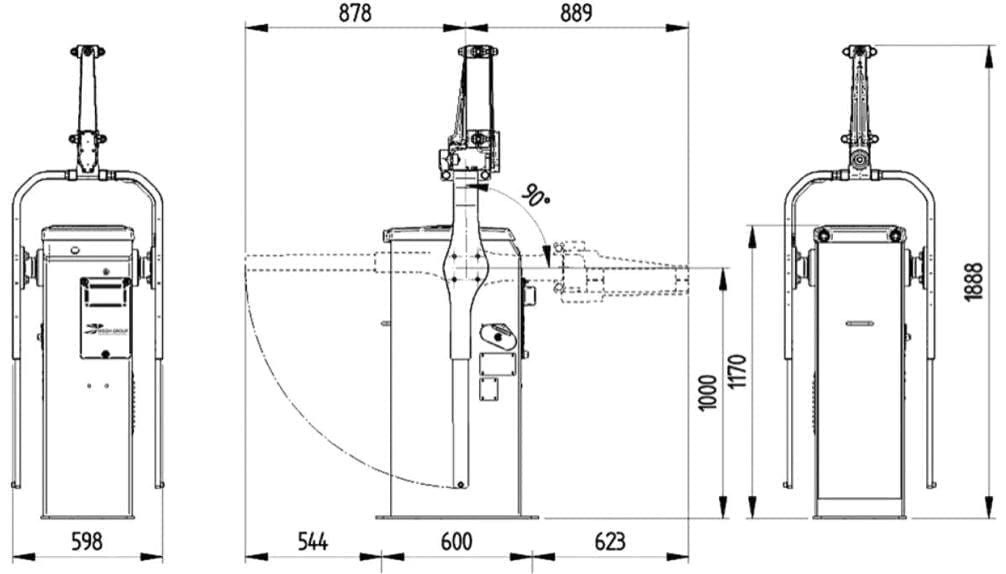

Data sheet

MAIN FEATURES

- Electro-hydraulic activation

- Very strong metal structure

- Mechanical lock in the raised and lowered barrier positions

- Electrical position control (barrier raised and lowered)

- Management of rod heeling with mechanical fuse and special electrical control

- Adjustable maneuvering speed and torque

- Torque limiter

- Emergency manual maneuvering

- Arrangement for rod light supply

OPTIONAL

- Environmental upgrade (TD96/3 version, suitable for particularly hot and dusty environments)

- Interior heater

- Internal electromechanical bell

- Timers for setting advance notice and maneuver timeouts

- Arrangement for powering street-side signal lights

- Rods of 4 – 5 – 6 – 7 – 8 m, with or without 3 red lights, with corresponding counterweights

- Metal frame for installation on concrete foundation

[/vc_toggle][vc_toggle title=”Technical Data”]Temperature range

-25°C ÷ +70°C

Weight

400 kg

Input voltage

24 V cc o 144 V cc

Control circuit voltage

24 V dc (48 V dc in the 144 V version)

Current drawn at rest

0 A

Rated current

10.5 A (2.2 A in the 144 V version)

Maximum current in friction phase

14 A (3.1 A in the 144 V version)

Opening/closing time

settable, 10 ÷ 15 s

Notice period (if any)

settable, 4 ÷ 60 s

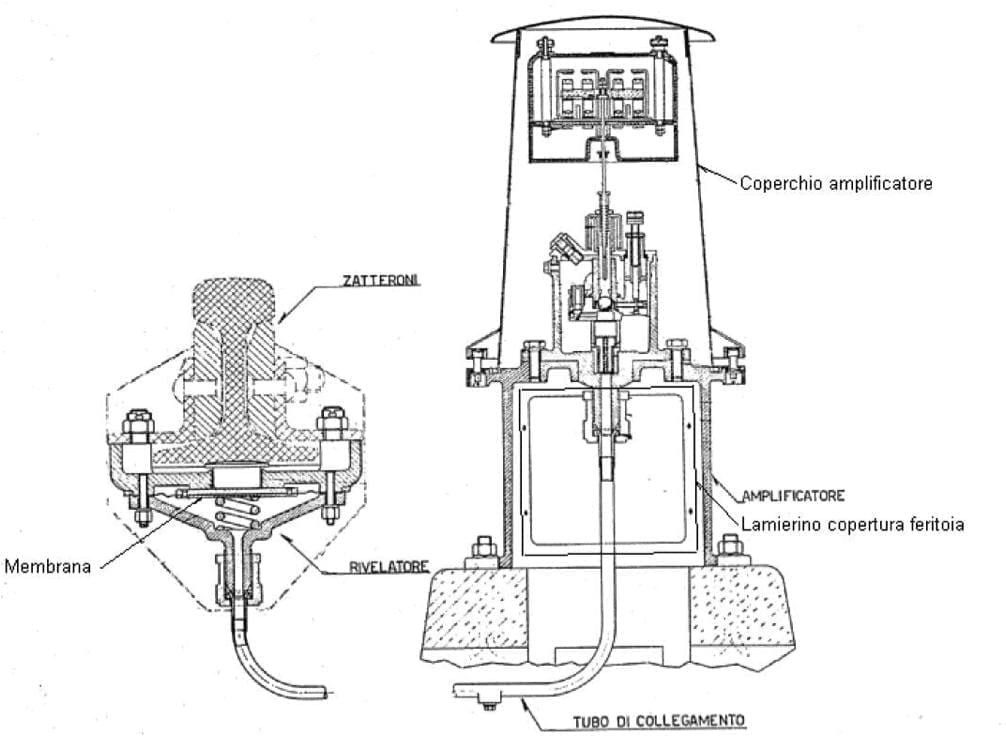

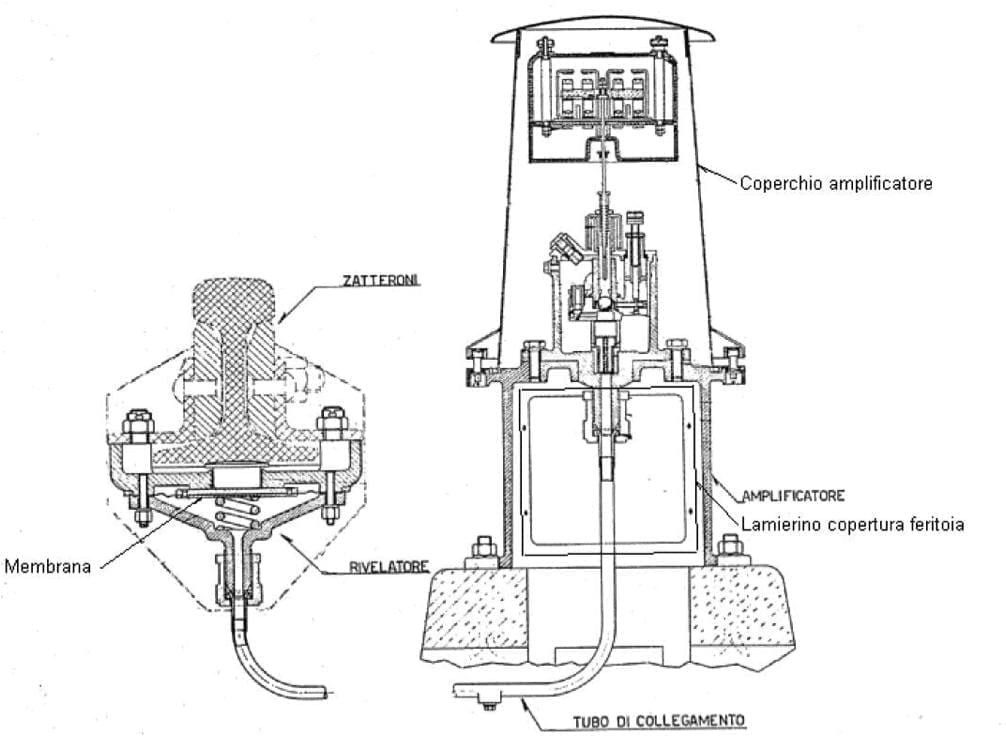

Data sheet

MAIN FEATURES

- Train detection by rail deflection measurement

- Compatible with rail armament 36, 46, 50, 60 kg/m

- Conforms to RFI supply specification IS 308 and is RFI approved

Technical Data

Switchable voltage

48 V cc

Switchable current

0,5 A

Number of diverted contacts

4

Data sheet

MAIN FEATURES

- LED diode light assembly

- Thermoplastic casing with side opening and fixing flange

- Lens made of unbreakable thermoplastic material

Technical Data

Rated supply voltage

12 V dc or 95 V dc

Current consumption at rated voltage

1.5 A (280 mA in the 95 V version)

Number of LEDs

200, grouped into 12 sectors

Temperature range

-25°C ÷ +70°C

Maximum relative humidity

95%

Dielectric strength

2000 x 1 min V ac

Isolation at 500 V dc

> 10 MΩ

Light intensity on the optical axis

> 150 cd

Outdoor visibility

> 100 m in a cone ± 15°